Palletizer Systems

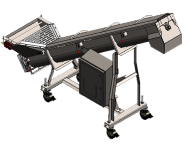

Unleash efficiency with our Robotic Palletizer System! Featuring advanced safety measures, it swiftly loads pallets up to 88”, handling hefty payloads of 35 kg. Elevate productivity, reduce labor costs, and ensure flawless end-of-line production. Ready to supercharge your operations?

Overview

Transform Your Operations with Robotic Palletizing

The next level of operational efficiency involves CHL’s state-of-the-art palletizing solutions. Designed to meet the demands of your end-of-line production process. With a focus on speed, precision, and reliability, our palletizers are the key to unlocking unparalleled productivity.

Features

CHL designs and implements palletizer solutions to meet all types of product and case packaging. Developed for your needs.

- High-Speed Performance: Achieve remarkable efficiency with our high-speed palletizers.

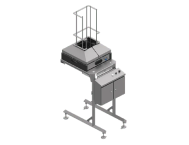

- Advanced Robotics: Equipped with the latest in robotic arm technology for precision handling.

- End Effector Tooling: Customizable end effectors to handle a wide range of products.

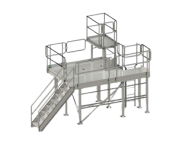

- Safety First: Advanced safety features to ensure a risk-free work environment.

- User-Friendly Interface: Easy-to-use controls for seamless operation.

- Flexible Design: Adaptable to various layouts and workflows.

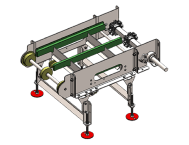

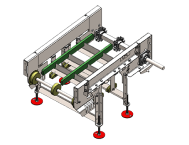

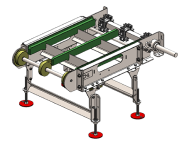

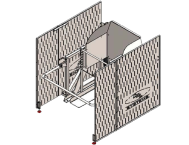

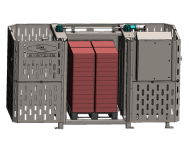

Standard Options Include

- M710ic/50H Robot

- Stainless Steel Tube and Lexan Guarding

- Left and Right Pallet Locations, serviceable by pallet jack or forklift

- Light Curtain guarding at pallet load

- Stainless Steel Robot Base

- Coval Venturi Vacuum style gripper, single case

- Infeed Conveyor (options: left, right, or center)

- Dropped Case Detection

- Loads pallets to 88″ depending on case size and pattern

- Up to 35 kg payload, typical cycles per minute greater than 10, depending on case configuration

- One single pick pattern