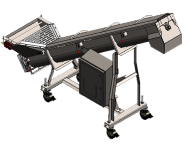

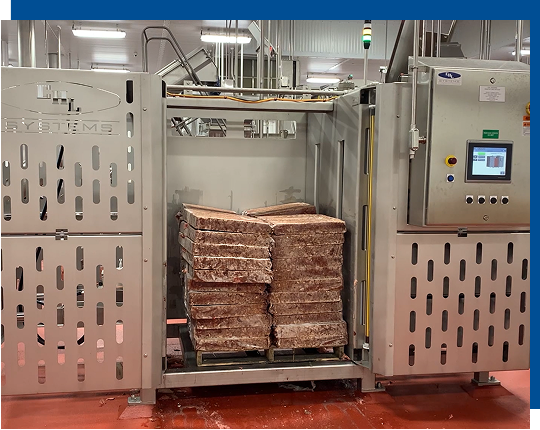

Frozen Block Separator

Our Frozen Block Separator conquers the challenges of separating large blocks of frozen food! Specially designed for pet food processing, it enhances safety, slashes labor costs, and supercharges productivity. Elevate your operations – let’s talk solutions today!

Overview

Say goodbye to manual block separation, prioritize employee safety, and boost your bottom line!

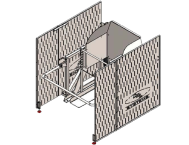

Designed specifically for pet food processing plants, the Frozen Block Separator is the ultimate solution for separating large blocks of frozen materials. It boasts a washdown ready build, light curtains for employee safety, heavy-duty stainless-steel spears for efficient block separation, and easy forklift loading and unloading.

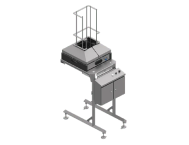

With our user-friendly interface, simply input the desired block thickness and choose the run mode, and the machine handles the rest.

The Frozen Block Separator is a stand-alone piece of equipment, set in place, wired, and ready to go. Contact us today to learn more!

Features

The Frozen Block Separator is a crucial addition for pet food companies processing bulk food frozen blocks, delivering substantial benefits in terms of safety and efficiency. Features include:

- Ergonomic Design: The FBS minimizes ergonomic challenges associated with manually separating large frozen blocks, enhancing

operator safety and comfort.; - Efficient Pallet Handling: Operators use a forklift to load full pallets of meat blocks into the machine.

- User-Friendly Interface: Intuitive on-screen display allows operators to input slice height and set controls easily.

- Advanced Safety Features: With a light curtain safety system and perforated stainless steel enclosure, the Frozen Block Separator enhances operator safety.

Specifications

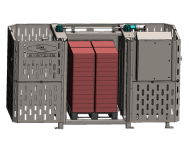

- Type 304 stainless steel construction

- Bead blast finish

- Washdown ready

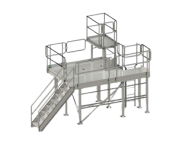

- Footprint: 9’ H x 12’ W x 7’ D

- Machine weight: 5,000 lbs.

- Accepts 40” x 48” pallet with up to 60” of stacked frozen meat

- Includes (4) stainless steel spears with hydraulic actuation

- NEMA 4X panel with Allen Bradley controls