Dumpers

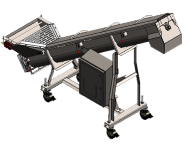

Our robust stainless-steel dumpers offer a hefty 3,000-pound lift rating, self-contained HPU, and versatile loading options. They conquer tough tasks with ease, minimizing maintenance and boosting safety.

Elevate your production – make CHL Dumpers your essential production partner today!

Overview

Dump your Downtime

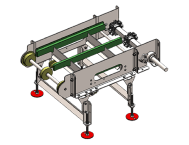

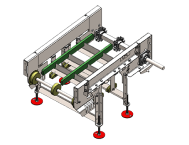

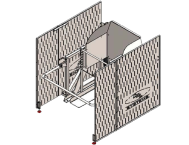

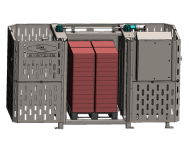

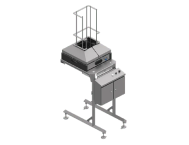

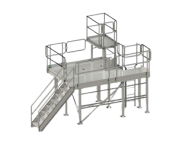

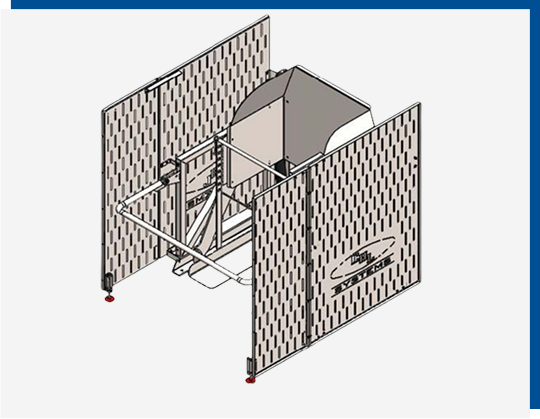

CHL Systems offers a robust range of heavy-duty dumpers designed to ensure uninterrupted material flow and reduce maintenance costs. Crafted from Type 304 stainless steel, these dumpers are built to endure rigorous industrial applications while offering exceptional longevity. Safety is paramount, with features like full guarding, an electrically interlocked safety pivot bar, and perforated side guarding. Custom discharge chutes and a generous 45-degree dump angle provide versatility. Trust in our 3,000-lb. capacity dumpers to streamline operations and enhance efficiency, accommodating totes up to 48″ x 48″ x 48″.

Features

CHL’s heavy-duty dumpers ensure uninterrupted material flow while reducing maintenance costs. Meticulously crafted, these dumpers guarantee longevity and peerless durability. Featuring:

- Full stainless steel guarding with perforations for enhanced visibility

- Electrically interlocked safety pivot bar

- Customizable discharge chute

- Self-contained HPU

- Adjustable product hold-down bar

- Configurable carriage for versatile loading options

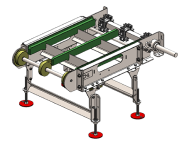

Specifications

- 60” pivot style dumper

- 45-degree dump angle

- 3,000-lb. load capacity

- Maximum tote size: 48” x 48” x 48”

- Type 304 stainless steel construction

- Bead blast finish

- Zero hollow structural members

- Stainless steel hydraulic cylinders