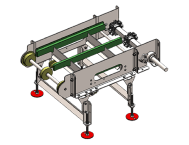

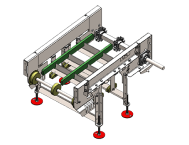

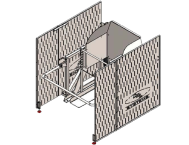

FT-1000

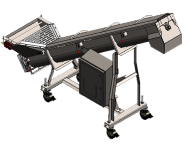

This highly configurable conveyor solution is built for versatile material handling. The FT-1000 offers optimal efficiency for a variety of applications from raw protein processing to box conveyance. With two levels of construction and a selection of custom add-ons, it meets every budget and sanitation need.

Overview

FT-1000 is a highly adaptable conveyor system ideal for simply moving products from A to B or processing products directly on the conveyor belt. With its robust construction and customizable design, this conveyor is built to deliver optimal performance in a variety of applications from raw protein processing to box handling and everything in between.

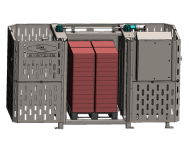

Choose from two levels of frame construction options and a list of available add-ons to best align with your budget and sanitation requirements.

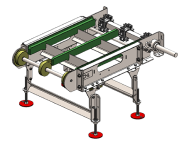

Features

- Modular plastic food-grade belting can accommodate washdown or sanitary environments.

- Built to last with 3/16″ stainless steel construction.

- Optional bolted or welded cross-members.

- Product containment options are fully configurable.

- Can be used with or without spacers between each section.

- Drive options include end drive, center drive, or tight transfer.

- Legs can be welded or bolt-together adjustable style.

- Standard options include belt lifters, drip pans or dustpans, and spray bars.