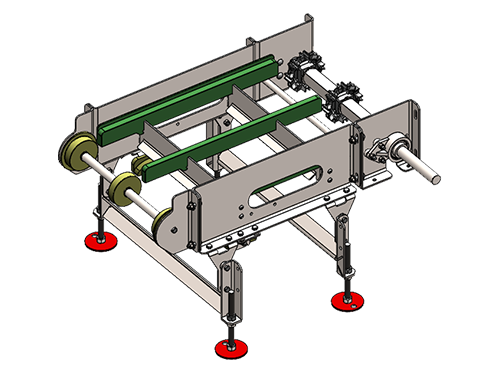

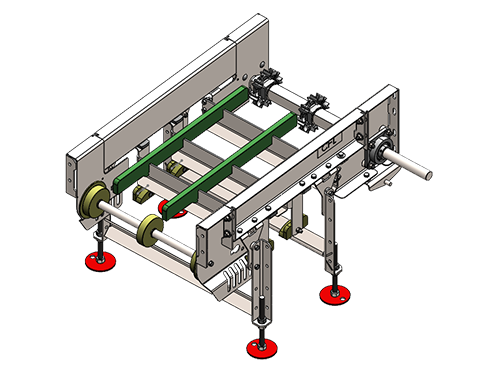

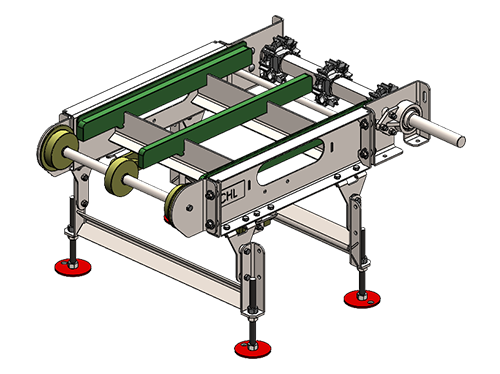

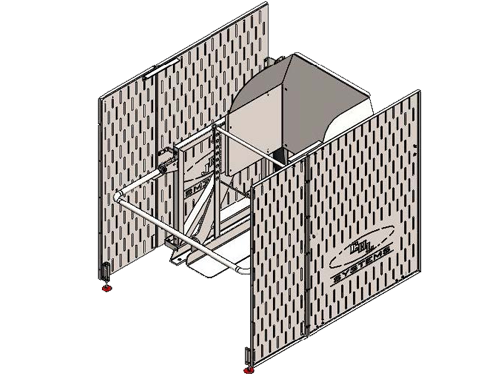

Hopper Takeaway

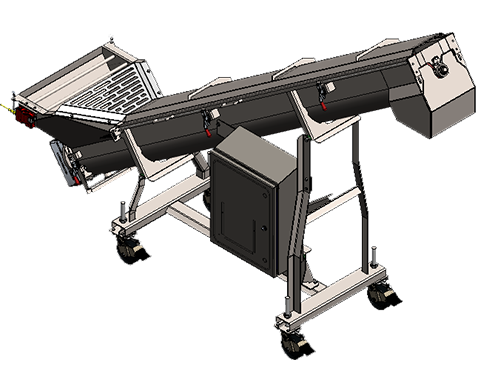

Hopper Incline Conveyor

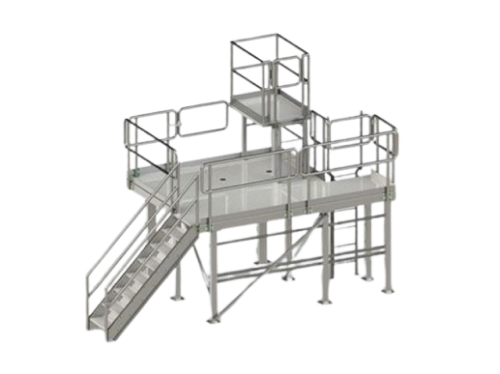

Sanitary Hopper Incline Conveyor for Reliable Material Handling

Whether used as a buffer for upstream or downstream processes, our Hopper Incline Conveyors integrate seamlessly into your existing systems. Engineered for durability and ease of operation, these portable units deliver consistent performance, even in the most demanding applications.

Hopper Incline Conveyor for Efficient Bulk Material and Raw Product Handling

Our versatile system pairs a robust, sanitary stainless-steel hopper with a precision-engineered incline conveyor, making it ideal for handling bulk raw products, dry goods, powders, or small packaged items. Engineered for reliability and ease of maintenance, this solution integrates seamlessly into your production line to enhance overall efficiency.

Key Benefits

- Sanitary Construction: Fully washdown-capable stainless steel design meets stringent hygiene standards.

- Customizable Options: Available in a range of sizes and configurations to suit your unique material handling needs.

- Enhanced Efficiency: Maintains steady material flow to prevent bottlenecks and ensure smooth operation.

- Ease of Mobility: Portable design allows for flexible positioning and easy integration across production areas.

- Reliable Performance: Built for continuous operation with minimal maintenance requirements.

CHL Systems’ Hopper Incline Conveyors offer the perfect balance of functionality, flexibility, and cleanliness. Whether you need to improve production line efficiency or handle a variety of bulk materials, our Hopper Incline Conveyor provide the quality and performance your operation demands.

Applications Include

- Feeding raw meats like beef cuts or chicken into grinders, mixers, or further processing equipment

- Transferring bulk raw or packaged products between production levels

- Handling dry goods, powders, and other materials in food processing

- Loading or unloading packaging and sorting machinery

At CHL Systems, we specialize in delivering conveyors to streamline workflow, and support productivity. From concept to completion, our team works with you to create solutions that meet the exacting demands of your production line while maintaining the highest standards of quality and performance.

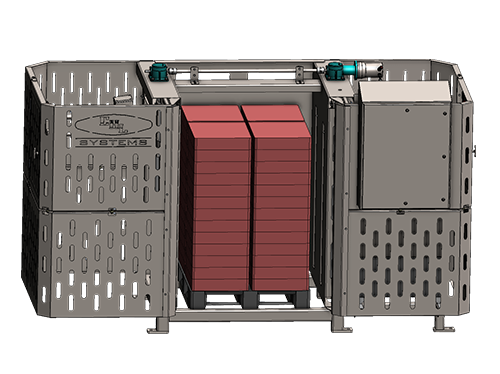

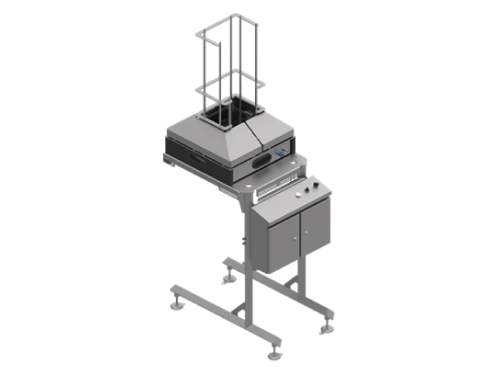

Key Features

- Sanitary Construction: Washdown-capable stainless steel designed for handling raw meat and other sensitive materials.

- Hopper Designed for Raw Product: Built to accommodate large volumes of raw cuts, poultry, or bulk materials, ensuring controlled feeding and reducing waste.

- Customizable Configurations: Tailored to your specific requirements with various hopper capacities, belt materials, and incline angles available.

- Durable and Reliable: Designed to perform in demanding environments, including meat and poultry processing facilities.

- Safety and Hygiene Features: Includes easy-access panels, safety guards, and smooth surfaces for thorough cleaning and operator safety.