As a food manufacturer, knowing the types of conveyors used in the food industry is one of the first steps in understanding what equipment will work best in your facility.

In this post, we’ll explore the details of various types of conveyors frequently used in the food industry, from how they operate to common applications. With this knowledge in mind, you will have a better understanding of how to leverage these solutions to your advantage.

Chain Conveyor

A chain conveyor is a type of mechanical conveyor system that uses a series of interconnected chains to transport bulk materials. The chains are fitted with paddles or scrapers that move the materials along the conveyor through a trough or tube. In the food industry, chain conveyors are ideal for gently moving fine materials such as grains or powders.

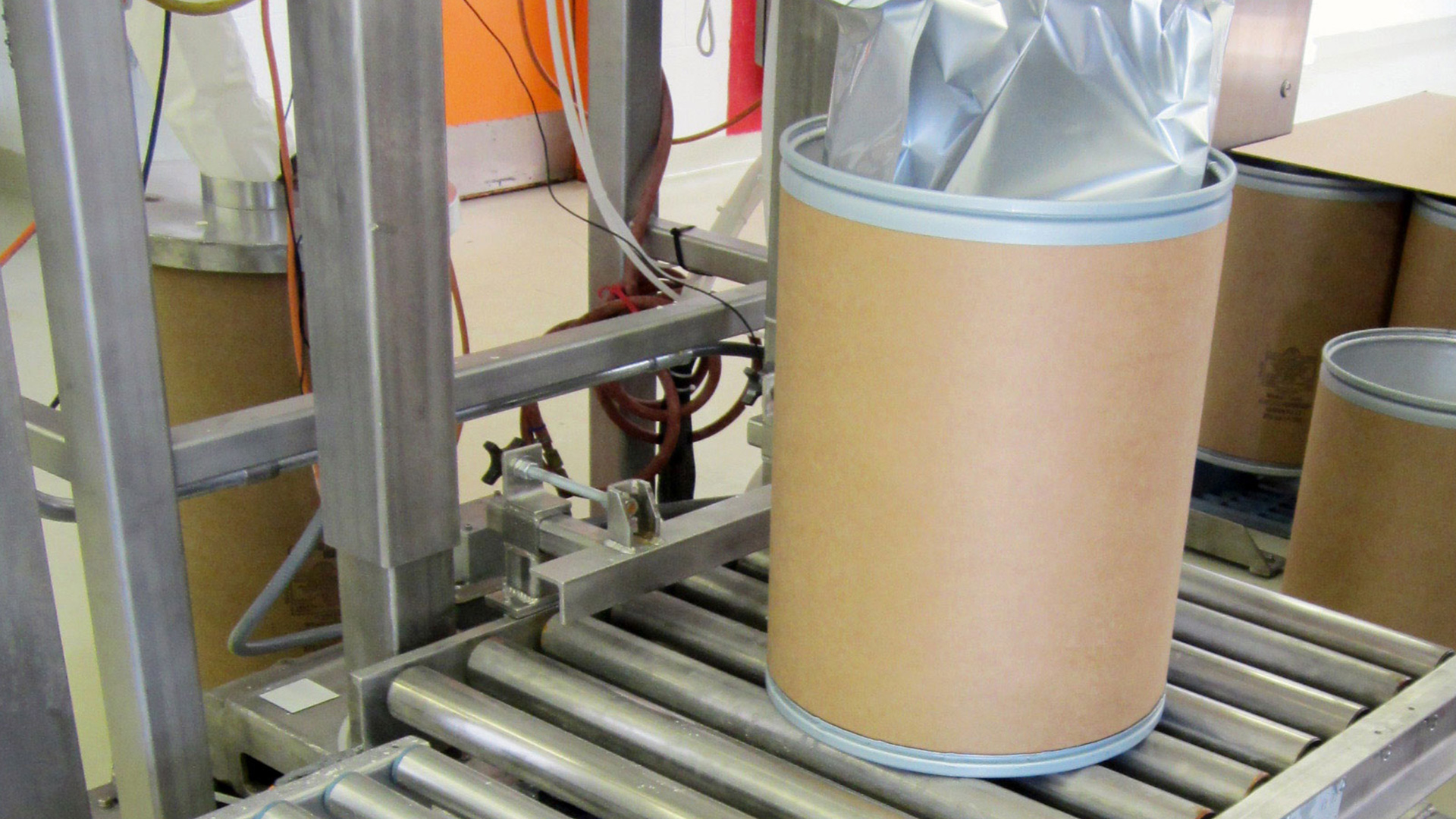

Heavy Duty Pallet Conveyor

A heavy duty pallet conveyor is a material handling system designed to move large and heavy pallets efficiently and safely within a manufacturing or distribution facility. These conveyors typically feature robust construction and are equipped with sturdy rollers, belts, or chains to support the weight of heavy loads. Heavy duty pallet conveyors are often used in conjunction with robotic palletizers and depalletizers.

Z-Conveyor

A Z-conveyor is a type of vertical conveyor system that is designed to move materials at different angles, including horizontal, vertical, and diagonal. It typically consists of a series of linked buckets that are attached to a chain or belt on a Z-shaped frame, over which the buckets circulate up and down. Z-conveyors are commonly used in food processing lines where space is limited and vertical conveying is required.

Screw Conveyor

A screw conveyor is a type of material handling system that uses a helical screw blade to move bulk materials along a trough or tube. The screw rotates to create a flow of material, which can be controlled by changing the screw’s speed and pitch. Screw conveyors are commonly used for applications such as mixing, heating, and cooling.

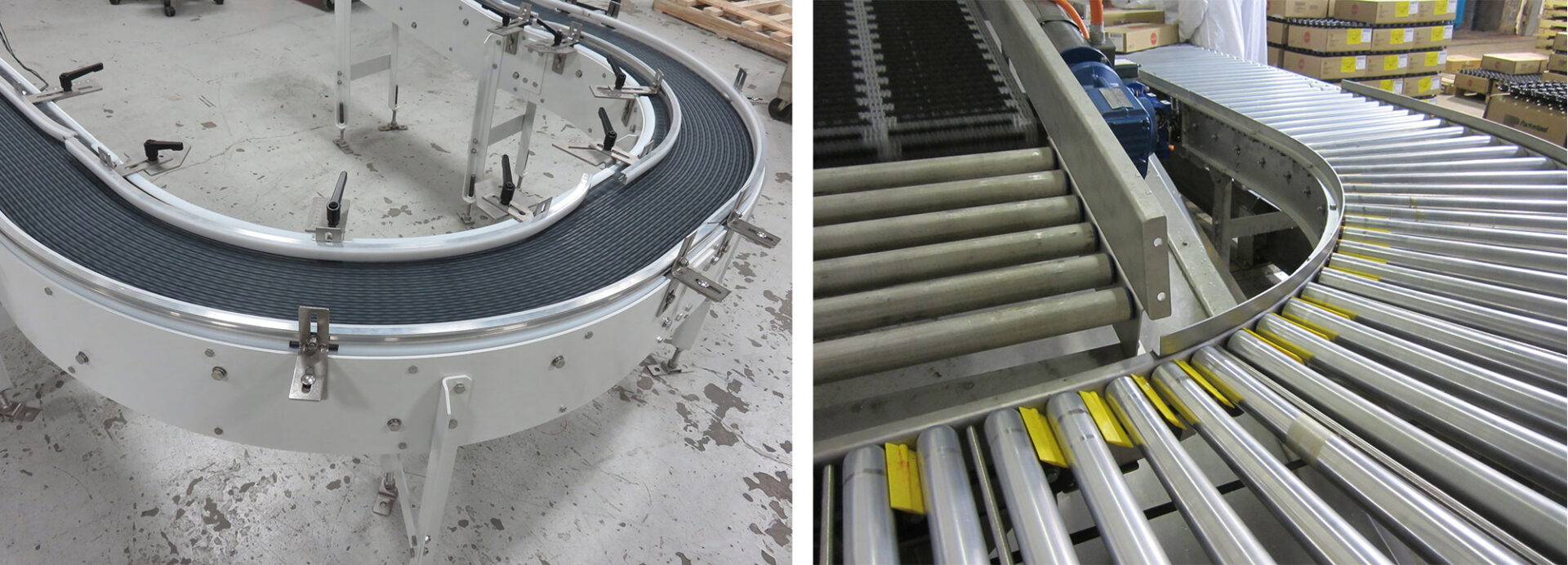

180 Box Conveyor

A 180 box conveyor typically consists of a curved section with powered rollers or belts that help guide and transport the boxes. These conveyors are commonly used to move products efficiently around corners and through tight spaces.

Weigh-Station Conveyor

A weigh-station conveyor is a type of conveyor system that is designed to weigh products as they move along the conveyor. These conveyors typically feature integrated scales or load cells that can accurately measure the weight of individual products or entire loads. Weigh-station conveyors are frequently integrated into packaging processes to ensure accurate and consistent product weight and compliance with regulatory standards.

Retractable Nose Conveyor

A retractable nose conveyor is a specialized conveyor system that features a retractable nose at one end, which can extend and retract based on the size of the product being transported. This allows for greater flexibility in transporting products of different sizes and shapes, as the retractable nose can provide additional support and stability for products with a tapered or pointed end. Retractable nose conveyors are commonly used for processes such as packaging delicate or uniquely shaped products, where flexibility and adaptability are key requirements.

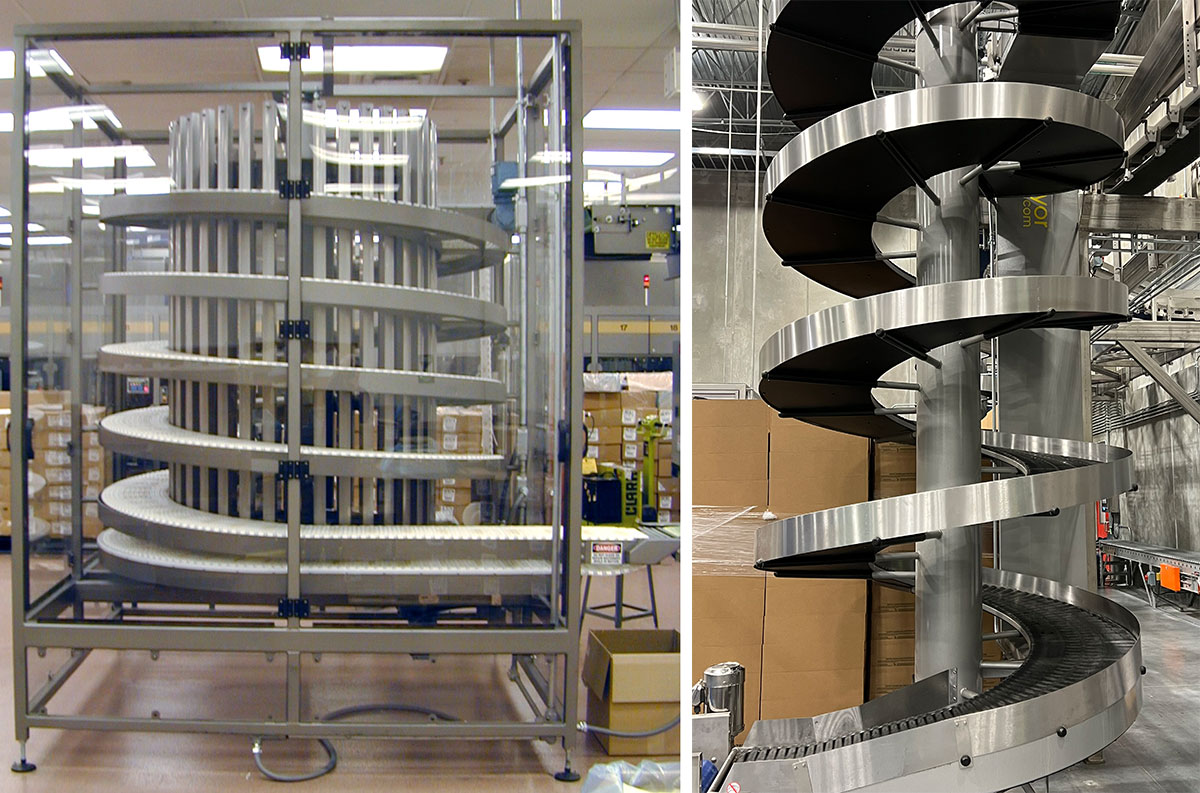

Spiral Conveyor

A spiral conveyor is a type of conveyor system that uses a spiral-shaped rotating belt or rollers to transport products vertically or horizontally between different levels of a building or facility. Spiral conveyors are commonly used in areas where space is limited and vertical transportation is required. They are also designed to handle products in a continuous flow, making them ideal for high-volume production environments.

Metal Detector Conveyor

A metal detector conveyor is a specialized conveyor that is equipped with a system that can detect metal contaminants and reject contaminated products as they move along the conveyor. These conveyors typically feature a metal detector head that is mounted above the conveyor belt or within the conveyor bed and can detect a wide range of metal contaminants, including ferrous, non-ferrous, and stainless steel. An essential part of every food production line, metal detector conveyors are used to ensure food safety and compliance with regulatory standards.

Bucket Conveyor

A bucket conveyor is a type of conveyor system that uses a series of buckets attached to a chain or belt to transport bulk materials vertically or horizontally. These buckets can be filled with materials and transported along the conveyor, then emptied at the desired location. Bucket conveyors are especially useful in moving large amounts of product gently and efficiently and can save floor space with their vertical conveyance capability.

Vibrating Conveyor

A vibrating conveyor is a type of conveyor system that uses vibrations to move materials along a conveyor belt. The vibrations can be generated by a motor or other mechanical means, which can be adjusted to control the speed and intensity of the vibrations. Vibrating conveyors are commonly used to carefully transport fragile or delicate materials that may be easily damaged. These conveyors are beneficial for applications such as coating or cooling where even product distribution is required.

Screen Conveyor

A screen conveyor is a specialized type of conveyor system that is designed to sort and separate materials based on size or other physical characteristics. These conveyors feature a screen or mesh surface that allows smaller particles to pass through while larger particles are retained and transported along the conveyor. Screen conveyors are an ideal solution for ensuring product quality and consistency during processing.

Slat Conveyor

A slat conveyor is a type of conveyor system that uses a series of slats or plates to transport products along a flat or inclined surface. The slats are typically made of metal or plastic and are connected by hinges or chains to form a continuous surface. Slat conveyors are commonly used for material handling and packaging where heavy loads or irregularly shaped products need to be transported.

Vacuum Conveyor

A vacuum conveyor is a type of conveyor system that uses a vacuum to transport products or materials along a conveyor line. The conveyor typically features a series of suction cups or a perforated belt that creates a vacuum to hold the product in place and transport it along the conveyor. Vacuum conveyors are commonly used in food processing and packaging where gentle handling of products and dust-free transport are required.

Takeaway

As you consider the advantages of implementing a conveyor system in your food processing facility, understanding your conveyance options is a good place to start. With this knowledge in mind, you will be ready to take the next steps in selecting an experienced conveyance partner to help guide you through each of the necessary considerations to ensure you are getting the solution that is the best fit for you.