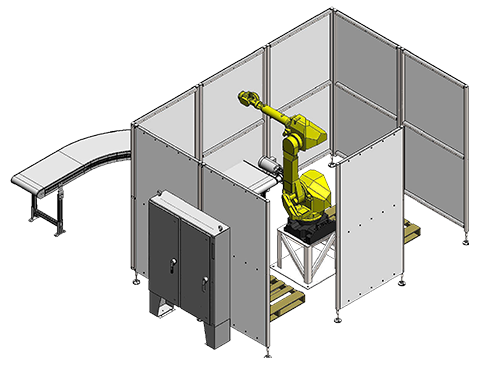

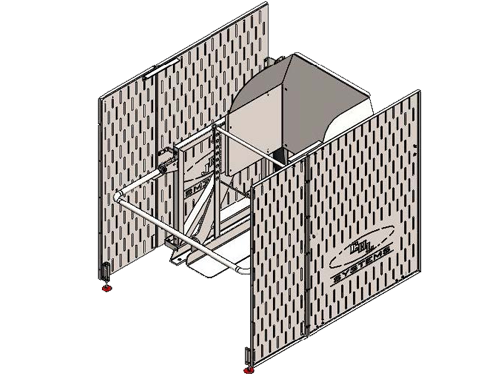

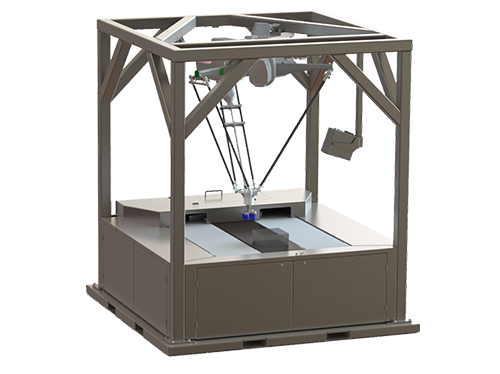

Delta Pick & Place

Experience streamlined processes, precise customization, and advanced automation — Supercharging your output with our Delta Pick and Place Cell, with high cycle rates and lifting capabilities, can propel your production to new heights!

Overview

Boost Your Production with the Delta Pick and Place Cell

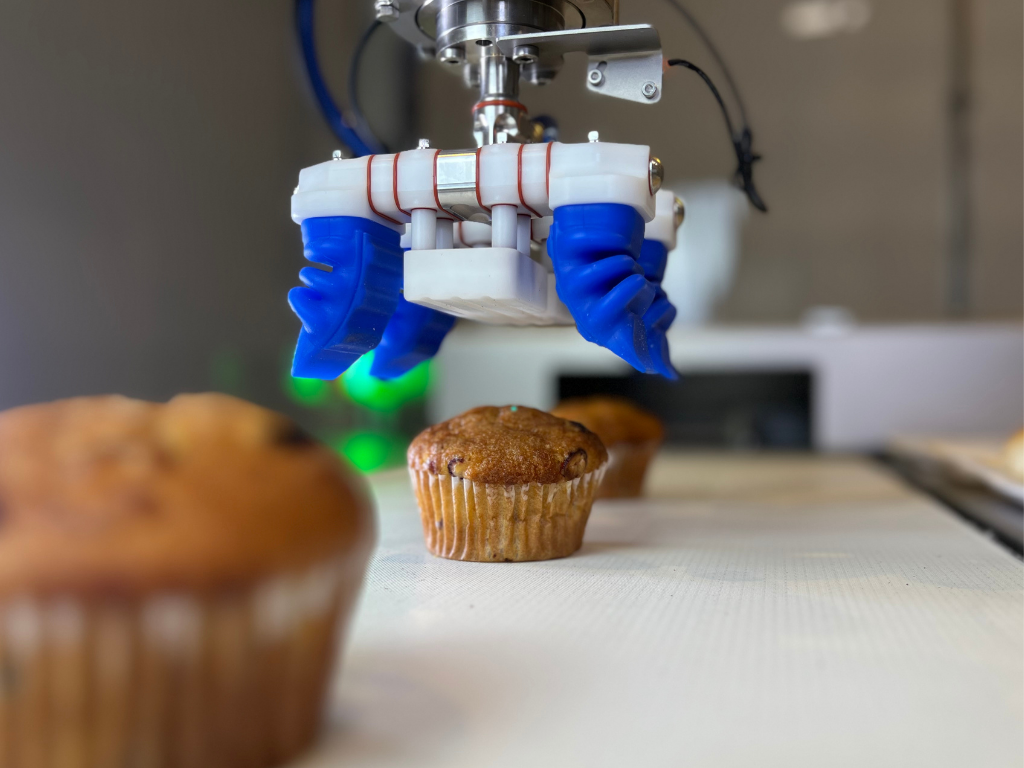

Experience unparalleled efficiency with the Delta Pick and Place Cell, operating at a blazing speed of 120 cycles per minute and capable of lifting up to 8 kg (Application Dependent). Engineered with IP69K protection, food-grade lubricants, a hygienic design, and the option of Electro Nickel Plate or FDA Epoxy Paint coatings, this cutting-edge Robotics Cell is primed for action in your food production plant.

Features

Versatility is at its core, with customization options that cater to your process requirements:

- Choose from various tooling options: vacuum tooling, Soft Robotics, or mechanical grippers, perfectly tailored to your application.

- Seamlessly integrate lane tracking for multiple conveyors, enhancing precision and control.

- Employ multiple robots simultaneously to pick, place, and package, multiplying your productivity.

- Embrace the future with AI, Machine Vision, and Machine Learning integration, allowing product reorientation, moving items on the production line, identification, and efficient picking from piles.

Applications

Packing Perfection

Efficiently pack delicate pastries and confections with precision, reducing product damage and ensuring uniform presentation. The Delta Pick and Place Robot enhances packaging quality while increasing production speed.

Frozen Efficiency

The Delta Pick and Place Robot excels at stacking or packing frozen meals or ice cream containers in frozen food production. Increase production efficiency while maintaining the integrity of frozen products.

Protein Sortation

Enhance meat and poultry processing by using the delta robot to precisely arrange cuts on trays. Ensure uniformity, improve hygiene, and meet rigorous food safety standards.

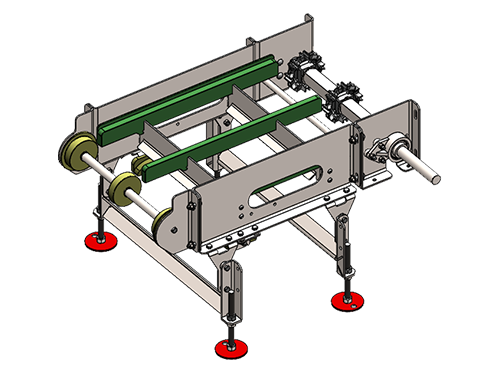

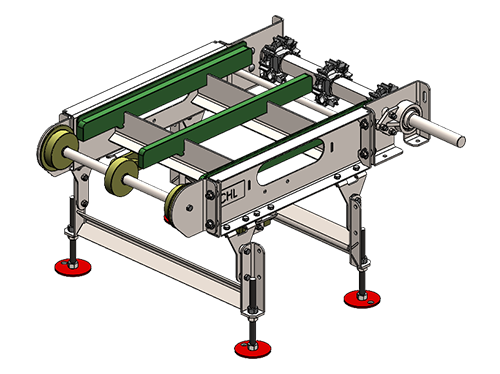

FT-1000

FT-1000 is a highly adaptable conveyor system ideal for simply moving products from A to B or processing products directly on the conveyor belt

Learn More

FT-4000

COMING SOON!

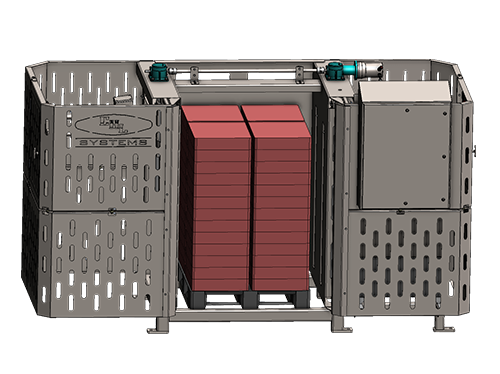

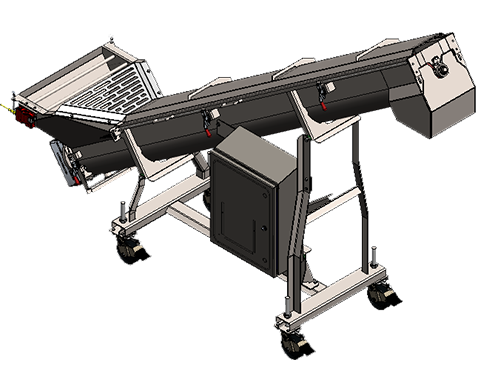

Frozen Block Separator

Revolutionize Frozen Block Handling with CHL's Frozen Block Separator. Designed for food production plants, it ensures safety, efficiency, and cost savings in bulk food processing.

Learn More

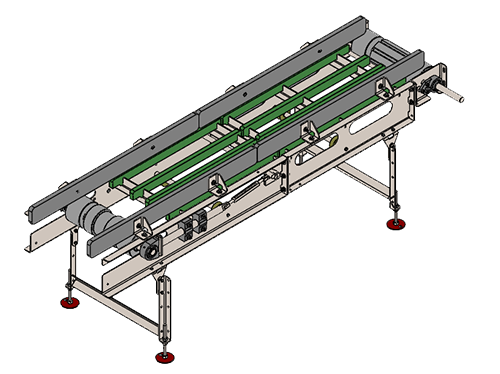

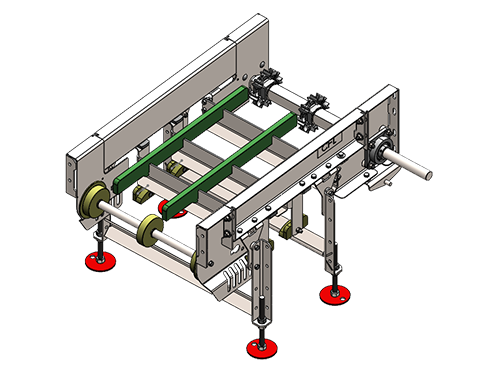

FT-2000

The FT-2000: Customizable, Hygienic, and Space-Saving Conveyor. Ideal for diverse industries, it offers easy maintenance, optional overhead suspension, and tailored configurations for your specific needs.

Learn More

Screw Conveyors

Versatile and customizable, our Stainless-Steel Screw Conveyors are essential for material handling. For short or long distances, flat or steep inclines, we tailor solutions to your production needs.

Learn More

Palletizers

CHL Systems' Robotic Palletizer: Efficient and Safe. With a versatile design, it handles up to 88" pallets and 35 kg payloads, streamlining your production. Ready to palletize your products?

Learn More

FT-3000

FT-3000: Robust and Customizable Conveyor for Heavy-Duty Applications. Built to last with a stainless steel frame, it offers exceptional strength, adaptability, and reliability for your unique needs.

Learn More

Dumpers

Discover CHL Systems' Stainless-Steel Dumpers: Sanitary, Durable, and Versatile. With a 3000-pound lift rating, they're ideal for tough applications, ensuring efficiency and safety.

Learn More

Delta Pick & Place