High-Speed Can-Filling

System

Project Overview

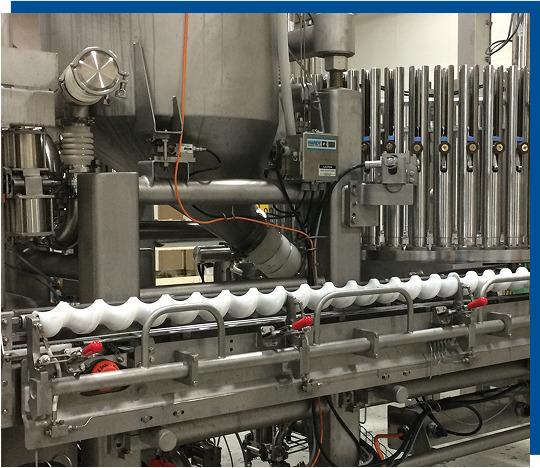

CHL Systems undertook a significant automation project for a nationally known food manufacturer, focusing on the design and implementation of a high-speed can-filling system. This project aimed to enhance production efficiency and maintain product quality during the food manufacturing process.

Key Challenges

- Achieving high-speed performance of filling 700 cans per minute for large can sizes

- Designing a system capable of handling a wide range of fill volumes (80 grams to 22 ounces)

- Reducing noise levels during operation

- Integrating with existing systems and accommodating various product types

- Ensuring efficient cleaning and maintenance processes

- Meeting stringent safety and quality standards in food manufacturing

CHL Systems’ Solution

Key Features

- Developed a new machine design to meet increased production demands

- Engineered a versatile filling system to accommodate various product volumes

- Designed custom solutions for seamless integration with client’s existing processes

- Implemented advanced features for efficiency and safety, including:

- No Can No Fill system

- Gradual cam system to minimize operational noise

- Stainless steel wire mesh safety guarding

- Integration with the client’s existing pig cleaning system

- Collaborated with Matrix Technologies for electrical work and PLC programming

- Provided comprehensive documentation and testing procedures

Results

- High-Speed Performance: Achieved target speed of 700 cans per minute for large can sizes

- Versatile Filling Capabilities: Fill volumes ranging from 80 grams up to 22 ounces

- Advanced Engineering: Complex mechanical design with gradual cam system

- Collaborative Integration: CHL Systems led mechanical design and collaborated with Matrix Technologies to handle electrical work and PLC programming.

- Comprehensive Testing: Setup of a test track conveyor for high-speed requirement validation

- Detailed Documentation:

- Drawing packages

- Operation manuals

- Standard Practice Instructions (SPIs)

The CHL Systems Advantage

This project highlights several key areas of CHL Systems’ expertise:

Custom Automation Solutions

Demonstrated ability to design and implement highly customized, complex automation systems tailored to specific client needs.

Food Industry Knowledge

Deep understanding of the unique requirements and challenges in food manufacturing, including safety standards and cleaning processes.

Collaborative Approach

Effective collaboration with other vendors and technology providers to deliver comprehensive solutions.

Comprehensive Project Management

From initial design to testing and documentation, CHL Systems demonstrated end-to-end project execution capabilities.

Industry-Specific Compliance

Expertise in adhering to the stringent standards and regulations of the food manufacturing industry.

High-Speed Processing

Proven capability in developing systems that operate at high speeds while maintaining precision and quality.

Integration Proficiency

Skilled at integrating new systems with existing equipment and processes, ensuring seamless operation.

Innovative Problem-Solving

Creative engineering solutions to address challenges such as noise reduction and variable product handling.

Quality Assurance

Rigorous testing procedures ensure that systems meet or exceed performance specifications.